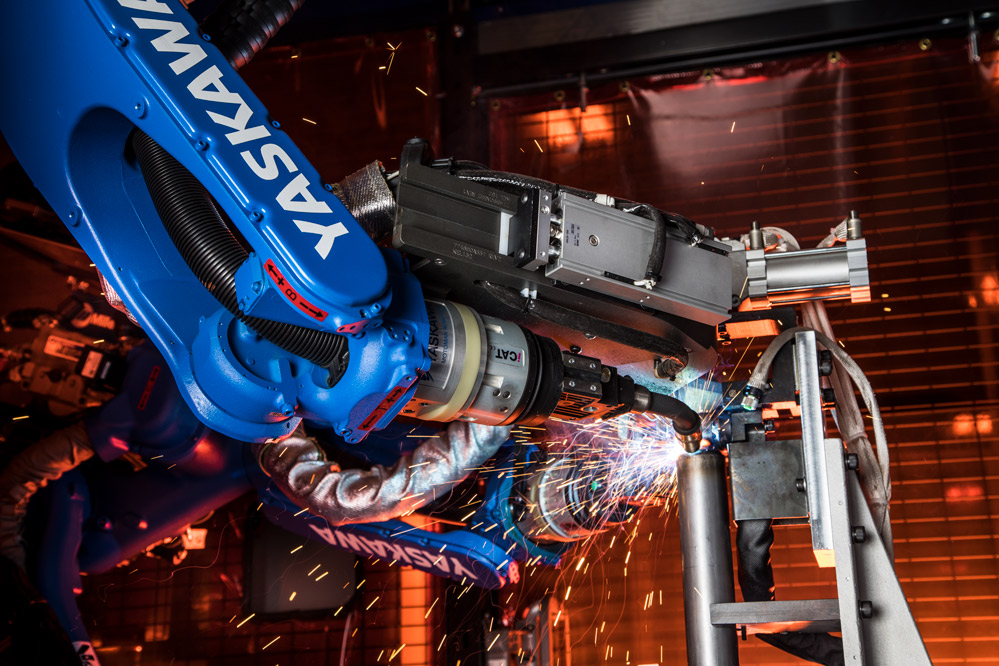

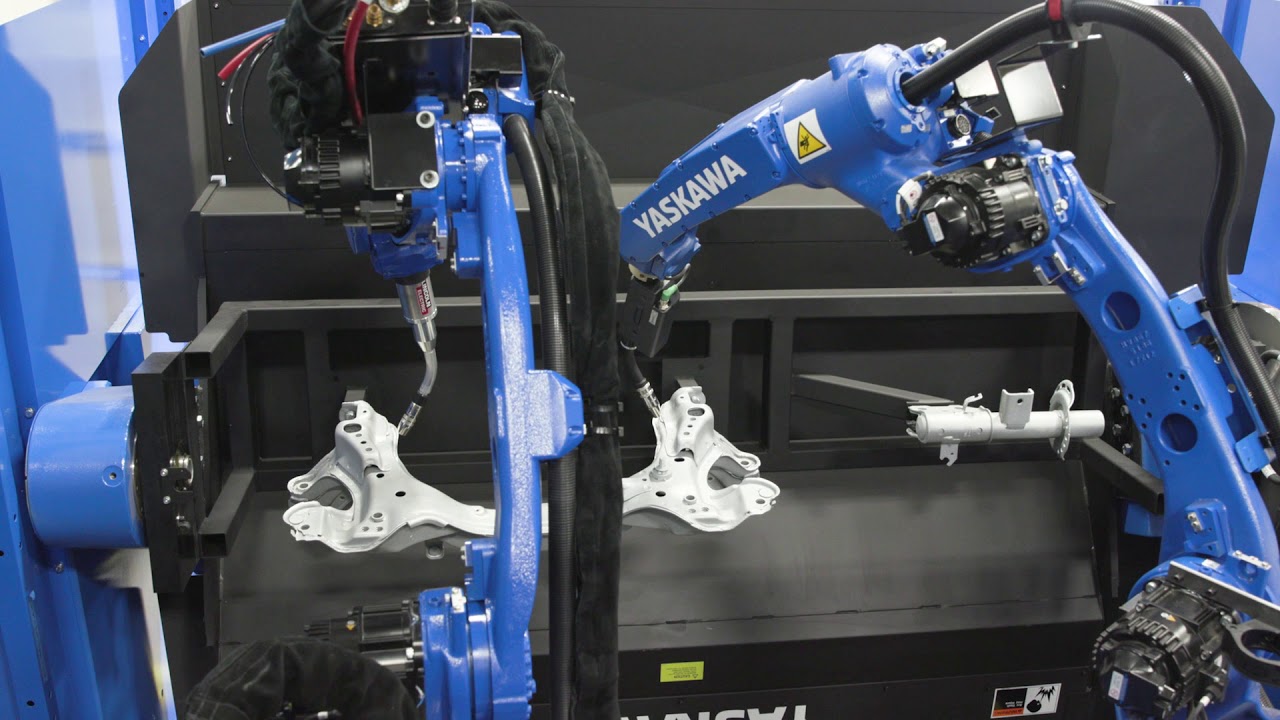

Welding with robots can deliver faster cycle times and consistent quality over manual welding. We use Yaskawa MOTOMAN robotic welding cells.

No one will contest the skill human welders bring to their work, but even the best welders simply can’t reproduce identical results each time. Nor can two welders produce identical weldments. Factors like part fit up, ergonomics, experience, and fatigue contribute to variation in quality. Depending on the specifications required, that can mean substantial time and money diverted to rework or scrap.

In contrast, an automated welding system can be programmed with the exact motions and parameters to complete a weld the same way every cycle. The outcome is greater consistency and higher quality. And because tolerances and fit have a cumulative effect, the better each weld is, the better overall quality of the finished assembly or product too.

To find out more or to discuss your project, give us a call now or fill out the form on our contact us page.