Continuing as a major sponsor for a sixth consecutive year. This long-term commitment highlights the strong relationship between the two organizations and their shared dedication to promoting women’s sports in Australia.

Continuing as a major sponsor for a sixth consecutive year. This long-term commitment highlights the strong relationship between the two organizations and their shared dedication to promoting women’s sports in Australia.

Metaltex is now a proud major sponsor of the Southside Flyers (WNBL) National Women’s Basketball League.

The club is based in Dandenong, Melbourne, Victoria. The team was founded as the Dandenong Rangers, however before the 2019–20 WNBL season began the team was rebranded to the Southside Flyers. Historically one of the better teams in the league, the Southside Flyers have appeared in the Grand Final five times.

The Southside Flyers is a fresh start for the team with fresh faces, fresh plans and a completely new look for basketball and women’s sport. The Australian women’s basketball team is ranked number three in the world and we want to build a culture and profile for this team and the sport that reflects this world standing.

The inaugural Head Coach of the Southside Flyers is Cheryl Chambers, one of the most successful and respected coaches in Australian basketball. Cheryl is a 3-time WNBL Coach of the Year and an Assistant Coach of Australia’s National Team, the Australian Opals.

Read more about The Southside Flyers in WNBL’s 2019/20 season.

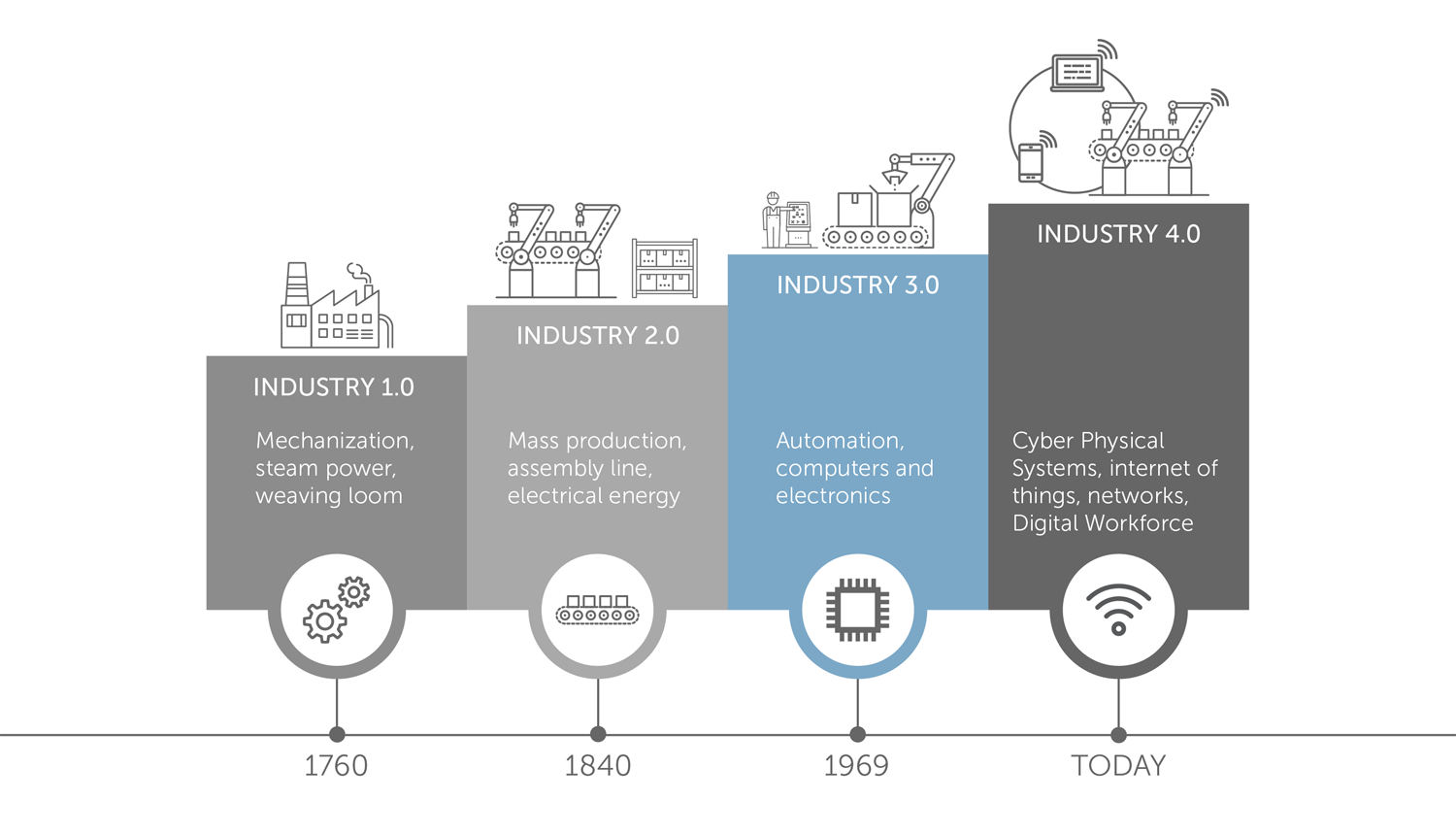

Metaltex Australia Pty Ltd has worked meticulously in the past 5 years to achieve technological advancement stage jump from industry 3.0 to latest gen 4.0. We relay you this excellent article on what Industry 4.0 is and how it will shape the future of manufacturing.

The adoption of digital technology has reached a point where we are ready for another radical change, the digital transformation of the industry or what we call Industry 4.0.

Industry 4.0, also known as the intelligent industry, is considered to be the fourth industrial revolution, a term coined by Professor Schwab and seeks to transform a company into an intelligent organization to achieve the best business results.

To some, it will seem too soon to talk about the next industrial revolution, i.e., the fourth industrial revolution, but the adoption of digital technology has reached a point where we are ready for another radical change, the digital transformation of the industry or what we call industry 4.0.

The change is based on the adoption of new technologies for the progressive automation of the production process. It is about innovative technologies whose application to the industry will be developed day by day.

We speak of additive manufacturing, collaborative robotics, production planning tools, artificial vision, virtual reality, gamification, process simulation, operational intelligence, IoT, and the so-called KET (Key Enabling Technologies).

All this implies the need to have systems that operate and manage broadband information and infrastructures for information technologies as well as buildings and traffic systems. This concept of industry 4.0 represents a significant leap for most organizations.

In Industry 4.0, automation and intercommunication are the basis for the optimization of design and production processes, which allows manufacturing of highly customized, flexible and efficient products. It affects the entire lifecycle of a product, ensuring its vertical and horizontal integration.

Starting with research, design, prototyping, production, distribution and client management as well as linked services, it interconnects all the agents involved that can react in a more agile way in the process. This leads to an increase in productivity and competitiveness as well as a significant reduction in costs.

In a Smart Factory, production control is absolute. The digital integration of information provides real-time access to the data, which will be chosen for each line, interest or user profile so that they are relevant to the business.

Both operators who have screens with information that promote efficiency in their position, as well as the data obtained in real time by executives of the company or department managers, provide the greater diagnostic capacity of the global situation of a factory and integration of effective decisions in the productive system.

The generation of a regular flow of information brings an effective value to the entire system, resulting in the more efficient management of resources, improvement of all processes and an interesting increase in profitability.

What do we know about Industry 4.0 or the fourth industrial revolution and why and what do we have to prepare for?

The fourth industrial revolution is a new era that gives a quantitative and qualitative leap in the organization and management of value chains. This new stage of the industry is committed to greater automation, connectivity and globalization.

Today, we see that the interrelation between different areas such as Products, Processes and Business Models has penetrated the industrial world, bringing with it the IoT and the world of Big Data and Analytics.

These are the technological advances that allow us to optimize manufacturing processes, their supervision and integration with other processes and systems used in a plant.

We live in an industrial revolution that consists of the fusion of the physical and digital planes, favoring the presentation of information in a comprehensible format for all users, promoting enhanced collaboration and data sharing, based on the automation of maintenance processes and artificial intelligence.

When we talk about an industrial revolution, we talk about technologies and tools such as, for example, virtual reality and augmented reality, IoT (Internet of Things), artificial intelligence and artificial vision, virtual assistants, Big Data, cloud computing, modern design programs and process simulation, 3D printing, security, Nano and biotechnology or quantum computing, among others.

Industry 4.0 is characterized by the quickest way to provide visible results and the degree to which it affects users. It is about the internet as a basis for interconnection and the implications this has in terms of the ease of access to information, digital identity, privacy, security, etc. are massive.

It is expected that Industry 4.0 will impact in some way the society, economy, and politics. It provides us with almost instantaneous information, which makes us more informed and more demanding.

Decisions are also expected to be made more quickly and efficiently when the fourth industrial revolution comes into the picture.

Our environment is already quite intelligent and poses many opportunities and challenges. An example is the creation of new smart products that present added values with respect to competition and have a positive impact on a person’s personal well-being.

The issue of cybersecurity is another example, and it will be one of the key issues for the interconnected industrial world. Of course, the industrial revolution also modifies the profile of human resources that will be needed in the new factories: skills and knowledge different from what is currently being asked for will be required, and it is expected that the work dynamics will be modified along with the schedules.

The question is not to be left behind and prepare for the fourth industrial revolution. The governments of many countries have already launched programs that aim to inform about different initiatives and support all types of training in terms of adapting companies to this new reality that requires more leadership and organizational changes to carry out business transformation.

Finally, manufacturers have been operating in a knowledge gap for too long, but now, the large volume of real-time data coming from the IoT, combined with operational intelligence technologies allows knowledge to be acquired and decisions to be made instantly.

Machine learning will be derived in predictive and self-adjusting processes. Using these tools will make the industry avoid mistakes or anticipate them, making it cheaper and shortening the productive process.

Innovative and visionary businesses working to keep Victoria’s manufacturing industry strong will be recognised at the manufacturing industry’s night of nights, the 2019 Victorian Manufacturing Hall of Fame Awards.

The theme for the 2019 Manufacturing Hall of Fame is Industrial Evolution – highlighting the resilience of Victorian manufacturing and the people who drive the industry, supporting hundreds of thousands of jobs. Minister for Jobs, Innovation and Trade Martin Pakula highlights the importance of recognising the outstanding achievements of the state’s manufacturing industry.

“Our manufacturing industry is innovative and internationally competitive, with strong growth in exports, business confidence and capital investment over the past year.”

Victoria’s manufacturing industry contributes more than $30 billion to the state’s economy annually and employs nearly 280,000 people – more than any other state.

“We know that recognising the outstanding achievements of the state’s manufacturing industry is important, and the Victorian Manufacturing Hall of Fame Awards are a vital part of this.”

The Hall of Fame has been running since 2001 and recognises Victorian manufacturers who have made an ongoing impact on the industry through innovation, investment and trade and supply chain connections.

Following a highly-competitive nominations and judging process, the finalists for the 2019 Victorian Manufacturing Hall of Fame Awards are:

Celebrating 40 years of operation in 2019, Metaltex Australia provides engineering, fabrication and CNC precision manufacturing of aluminium, stainless and mild steel products. Metaltex Australia is leading Original Equipment Manufacturer (OEM) company with national and international clients across a range of industries including: automotive, aerospace, defence, infrastructure, mining, energy, rolling stock, food processing, point of sale material, water transfer and storage, agriculture, electronics and general manufacturing.

Metaltex Australia has expanded rapidly over recent years, embracing the principles of Industry 4.0 manufacturing, focusing on its people, and investing in state-of-the-art equoment and technologies. In 2017, Metaltex Australia moved into its new purposebuilt manufacturing facility in Dandenong South. This has enabled the company to expand its contract manufacturing capability, improve its quality, precision and put it in a highly competitive position to achieve import replacement for Australian supply chains trading in local and global markets.

Metaltex is committed to ensuring the industry remains competitive in the future and undertakes cross skill training amongst all production staff.

Our manufacturing capacity have updated and keep evolving to higher precision technology, more skilled work force and efficient work flow. As Industry demands and expectations increase so too will the investment in our capabilities, facilities and services. We will continue to invest time, energy and money in order to broaden and expand our client base.

Metaltex has a world class facility providing a range of in-house manufacturing capabilities that are scalable to suit domestic and international applications.

Our capabilities include:

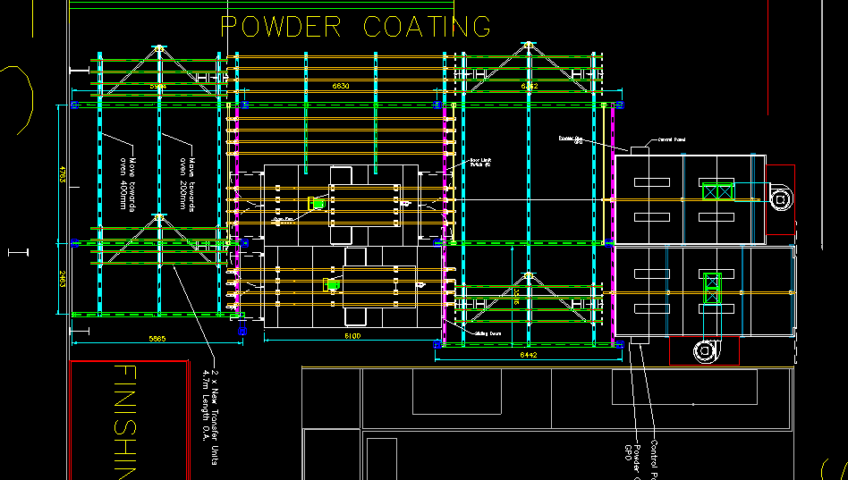

Metaltex has just ordered our second powdercoat line form Garnic Technologies. The new line will comprise of a 6.3 meter long x 3.1 meter high batch oven that is supported by a VSD recirculation fan in conjunction with a fully modulating high low gas burner through a combustion chamber which gives the batch oven even temperatures from top to bottom. In conjunction the oven unit also comprises of 2 overhead high temp transfer stations capable of transferring product up to 6.2 meters long and a Powder coating booth that comprises of a 18KW high efficiency dust collector that has fully automated reverse pulse Spunbonded Polyester filters and a digital Gema Optistar application gun.

Commissioning of the unit is expected to commence in May.

Our first Oven has been in operation almost 1 year now producing exceptional results and quality hence the additional purchase to further increase our capacity.

Metal fabrication is used to make everything from car parts to office equipment. Galvanized steel paperclips are fabricated by design, cutting, and forming.

Metal fabrication melbourne for diverse uses is a typical process. Metalworking includes cutting, shaping, melting, bending, and assembling.

As you probably guessed, industrial metal fabrication involves assembling and integrating different parts or assemblies composed of metal, usually sheets or plates, into finished industrial goods.

Many sectors rely on industrial fabricators, including aerospace, alternative energy, water treatment, pollution engineering, material handling, and automotive, among many others. Their wares are typically massive in size and comprise things like silos, tanks, and components for heavy machinery.

In contrast to structural metal manufacturing, which will be covered later on, industrial metal parts are usually utilized in conjunction.

Builders increasingly use high-strength structural metal for commercial, industrial, and residential projects. Structural metal fabrication creates I-beams for these uses.

Steel is preferred for structural manufacturing due to its strength-to-weight ratio. Almost every building project uses steel.

In a business context, the steel is the main component that helps to build the structure. The Empire State Building, Sydney Harbour Bridge, and Burj Khalifa use structural steel.

Building projects may use sheet metal folding melbourne:

• Turrets, or specialized building components that allow for more efficient manufacturing

• Platforms, which are common in many buildings and can be found in storage areas, ramps, decks, and loading bays

• Walkways (which must normally conform to several OSHA regulations to be used in industrial settings)

• Stairs, in situations where sturdiness and longevity are vital in a home, business, or factory environment

• Building components such as girders, beams, and trusses

Commercial aluminium fabrication melbourne includes producing components used in commercial establishments such as stores, restaurants, public areas, and government structures. Some examples of metal products sold in stores are:

• Guardrails

• Awnings

• Shelving

• Appliances like sinks

• Conveyors

Ornamental metal is another form of commercial Metal fabrication melbourne. Installing these metal products outside of business buildings is a common way to improve the buildings’ visual appeal and attract more customers.

Metal components used in commercial applications are often more refined and compact than those used in structural and industrial applications. But they’re equally crucial to a business’s functionality and the safety of its staff and consumers.

Metalworking has existed for millennia, yet its methods and tools have changed. Metalworking has advanced in recent centuries, yet many of the essential techniques have been present for a long time. Modern aluminium fabrication melbourne technology has many applications, but a few of the most important ones include:

CAD software

CAD software is essential for metal manufacturing project design. Engineers can draw plans for fabrication companies using CAD software. This software system makes the development of 3D models and the implementation of quick design changes possible. CAD software also facilitates the translation of designs into programming languages, which is essential for programming fabrication machinery. Engineering can now swiftly determine structurally problematic areas, and computer-aided design has simplified component fine-tuning.

Automation

Automation has transformed manufacturing in recent years. More fabrication equipment is programmed to work independently and with minimum human input. This allows for round-the-clock operation, which in turn improves accuracy and repeatability. Among the many processes that automated instruments are supplied for are cutting, welding, folding, and machining procedures.

Machinery

As technology progresses, so do solutions for machines. Using lasers in cutting processes makes short work of even the thickest materials. Plasma and waterjet cutting, among others, are quickly expanding their reach. A wide range of applications and materials can benefit from these strategies.

Metaltex is a Melbourne-based sheet metal folding melbourne manufacturing company with over 30 years of experience. We have deep engineering and sheet metal experience and a robust supplier and partner network. Metaltex uses state-of-the-art sheet metal CNC equipment to guarantee that every sheet metal project is meticulously executed to the highest standards of quality and accuracy. Our production turnaround is lightning-fast, and our pricing is lower than the competition.

We are glad to inform our customers that a Durma Hydraulic 4-Roll CNC plate roller has been added to our manufacturing capabilities for sheet metal products.

The Durma Hydraulic 4-roll plate roller helps us achieve shorter cycle times while making it possible to be less dependent on operator variables. As with all manufacturing stages, with sheet metal rolling we aim for repeatable precision and quality. 4-Roll Plate Rolls are more precise, productive, versatile, faster safer and easier to the operator than 3-Roll machines. Thanks to the high torque drive system, these Durma rollers are ideal for bending plates up to 200mm thickness.

New Trumpf precision robotic bending cell due in at Metaltex later this year 2021. We’ve further invested in increasing our hight standards for manufacturing precision and repeatability of targeted quality that excells customer expectations.

Manufacturer description: The TruBend Cell 5000 is the perfect solution for all those who value productive and flexible #automation, for the widest possible range of parts. The quality remains consistently high. With the newest series of the bending machine #TruBend 5000, the bending cell is state of the art, for example in the areas of programming and angle measurement. Select the #bending machine and #BendMaster according to your individual range of components. You also have maximum freedom in the design of the material flow using conveyor belts and pallet conveyors.

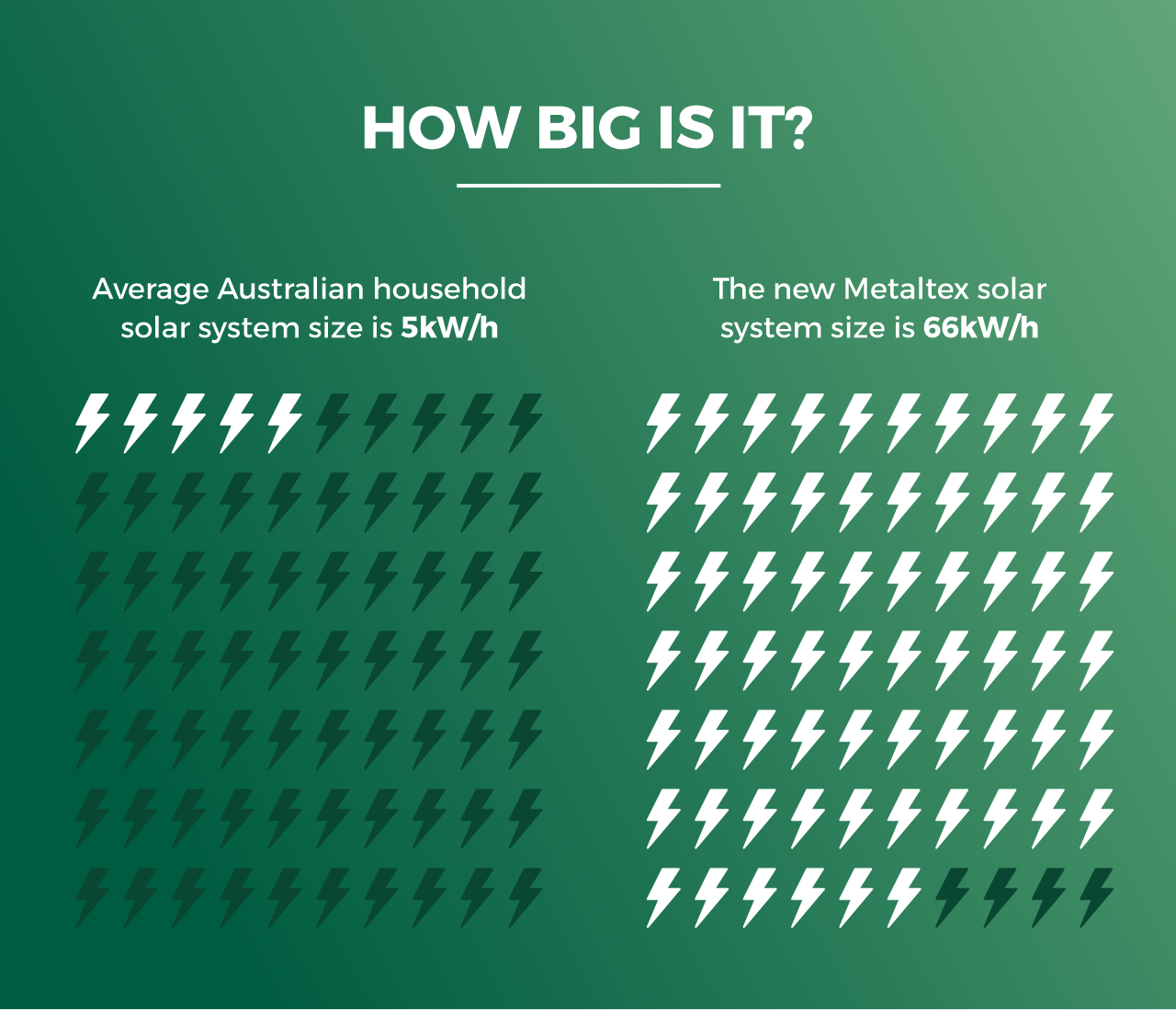

Metaltex is in the process of having a 66KW Rooftop Solar panel system installed on our new Factory. The installation will not only reduce our carbon footprint but will significantly reduce our operations electricity consumption. Our dedication towards adopting Industry 4.0 model includes using renewable energy and digital technology working together in synergy for higher efficiency of manufacturing. This brings Metaltex in the family of today’s Smart Factory movement and our capabilities at the very pinnacle of contemporary Green Energy Manufacturing solutions.

The chosen company that is conducting a feasibility study and whom will also be actioning the install is Energy-Tec. They are Western Australia’s leading sub-meter reading and billing specialists, with over 25 years’ experience as trusted advisors.

“Industry 4.0 could contribute to finding new ways of dealing with major global challenges, such as climate change, lack of clean energy access, economic stagnation and reducing the digital divide.

The sustainable energy transition and Industry 4.0 share important characteristics that can be interconnected to pursue a sustainable energy transition. Such integrated approaches could be guided by the SDGs, which provide important target setting for energy, climate action and beyond.”